product

facade ceramic

Delta Elements FACADE CERAMIC is made of dry pressed, double fired porcelain stoneware. The product is solid-colored, rectified and optionally with adhesive coating on the reverse side.

It is available in plain grey or brown shades and in various natural stone looks.

Areas of application

– As wall and ceiling cladding interior/exterior

– As cladding on exterior wall insulation systems (EWI systems)

– As cladding on suspended, rear-ventilated plaster support systems

Classification according to EN 14411 ISO 13006 Annex G Group BIa with E ≤ 0.5% UGL, fire protection class A1 (with adhesive coating B1)

* The maximum permissible area sizes or edge lengths in accordance with the specifications in the General Building Inspectorate Approvals (ABZ) of the facade system manufacturers must be observed.

VALS

PORTLAND

SLATE

TRAVER

PLAIN2

WOOD

SANDSTONE

Standard Format

30 x 60 cm

Special Formats

Depending on series

60x60 cm

60x120 cm

120x120 cm

Cuts on request

Material Thickness

depending on series

6-9 mm

Surfaces

series depending

smooth

rough

structured

PRODUCT FEATURES

- Applicable according to general building approval for EWI systems (up to 30x60 cm) and ventilated facade systems

- Dry pressed, double fired porcelain stoneware, solid-colored and rectified

- Classification according to EN 14411 ISO 13006 Annex G: Group BIa

- Various series, surface textures, formats and colors available

- Formats & colors can be combined/ Format mix

- Natural stone character is reproduced true to nature

- Optional factory-made adhesive coating according to DIBt specifications

- Low water absorption and wet stretching, high dimensional accuracy

- High resistance to stain and chemicals

- High shock and impact resistance also on EWI systems

- Good abrasion resistance and high breaking strength

- Easy removal of paint smears/graffiti

- Resistance to frost, de-icing salt, temperature changes and UV radiation

- Low porosity with a low water absorption of <0,5%

- No efflorescence or discoloration as with natural stone

- No staining, sanding or algae formation

- High color fastness/ no color or structure variations

- Absolutely UV-resistant and no light reflection, without mirror effects

- High fire protection classification: A1 (with adhesive coating B1)

- Very similar color batch and calibre for repeat orders

- Various floor, stair and wall claddings also available for interior and terraces

FACADE SYSTEMS

Delta Elements FACADE CERAMIC may be applied on different substrates. Here you can find constructional information and documents for the application of FACADE CERAMIC on EWI systems. We would be pleased to work with you on solutions for project-specific construction- and details-solutions.

All specifications and drawings do not constitute any guarantee in regards to the recommendations provided. Delta Elements assumes no liability and refers to its general business terms and conditions. No rights of any kind can be derived from the contents of this information. The respective current version and the general business terms and conditions can be found at www.deltaelements.eu; printing errors reserved.

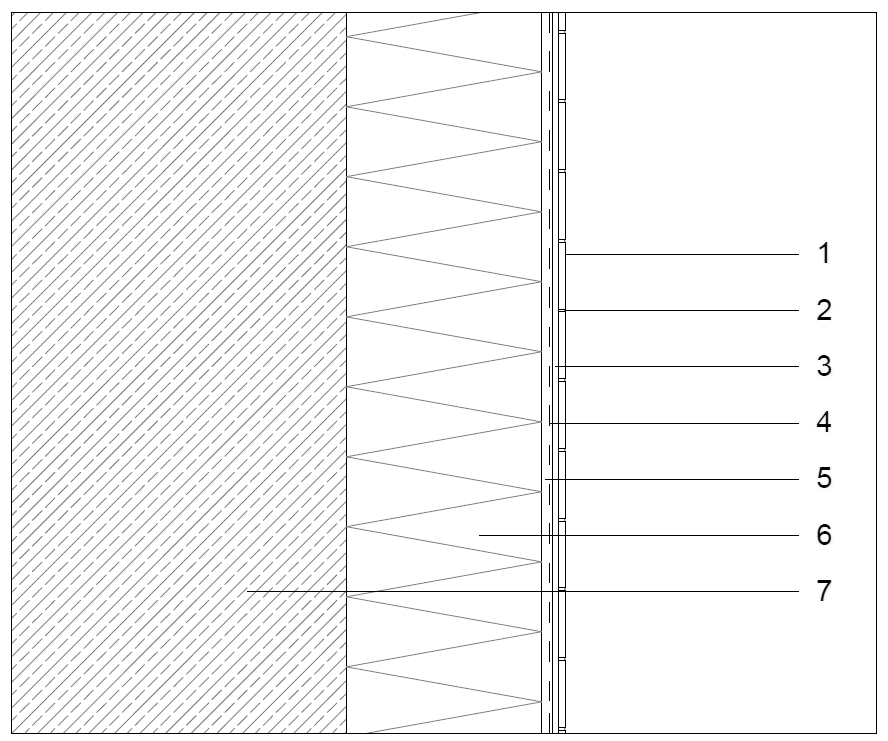

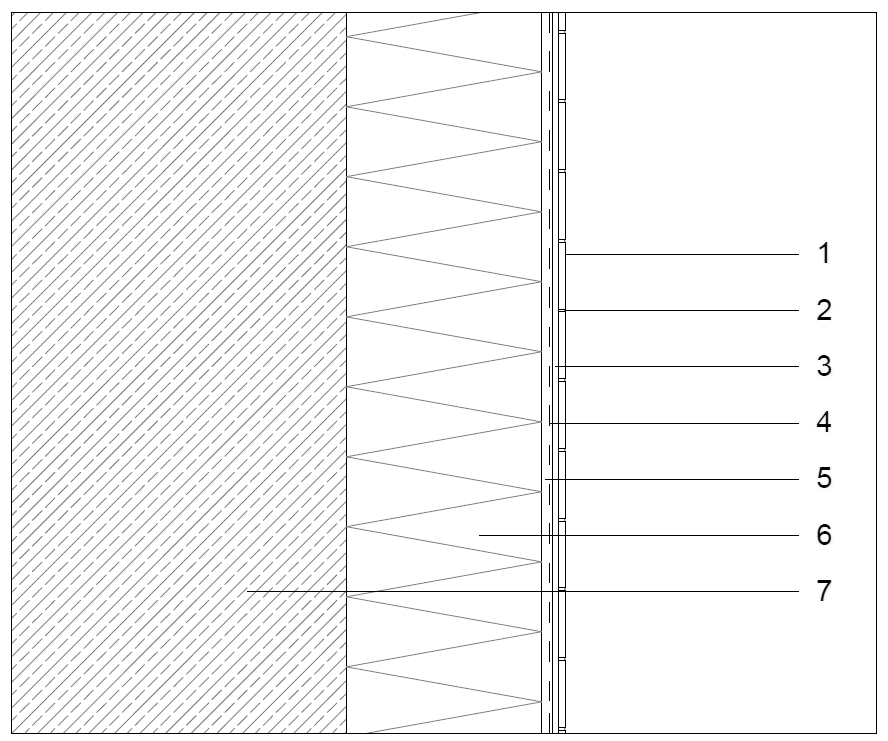

Delta Elements FACADE CERAMIC can be processed on exterior wall insulation systems (EWI system) which are certified by construction authority. Our processing instructions, the processing instructions of the facade system manufacturers and the below listed DIN norms and guidelines have to be observed. You will find our processing instructions at the download center. Further technical information is available on request.

1 Delta Elements FACADE CERAMIC

2 System-joint mortar, slurry method (except Vals struc)

3 System-adhesive mortar

4 System-equalizing mortar layer

5 System-basic plaster with textile

6 System-thermal insulation plate, doweled through the textile

7 Sustainable massive ground

Standards and directives

DIN 18157 Installation of ceramic coverings using the glue-fixing method

DIN EN 12004 Mortar and adhesives for ceramic tiles and panels

DIN 18352 Tiling and paving

DIN 18515-1 Exterior wall cladding – tiles or panels applied with mortar

DIN 18540 Sealing exterior wall joints in building construction using joint sealing compound

DIN 18202 Dimensional tolerances for building construction

DIN EN 14411 Tolerances for ceramic tiles and panels

ZDB-leaflet: Expansion joints in tile and panel cladding and coverings

All specifications and drawings do not constitute any guarantee in regards to the recommendations provided. Delta Elements assumes no liability and refers to its general business terms and conditions. No rights of any kind can be derived from the contents of this information. The respective current version and the general business terms and conditions can be found at www.deltaelements.eu; printing errors reserved.

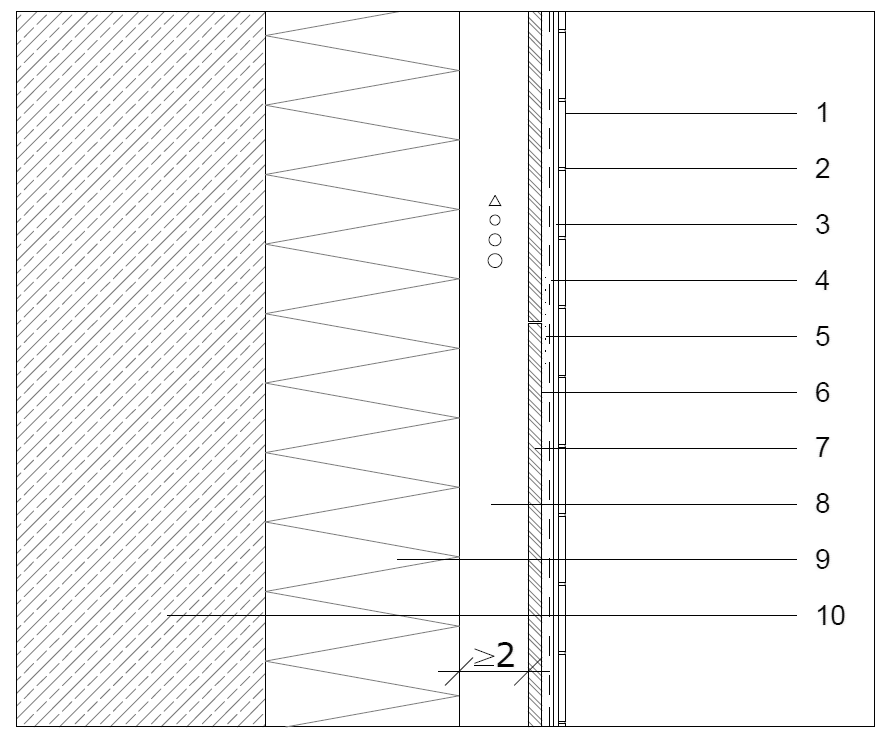

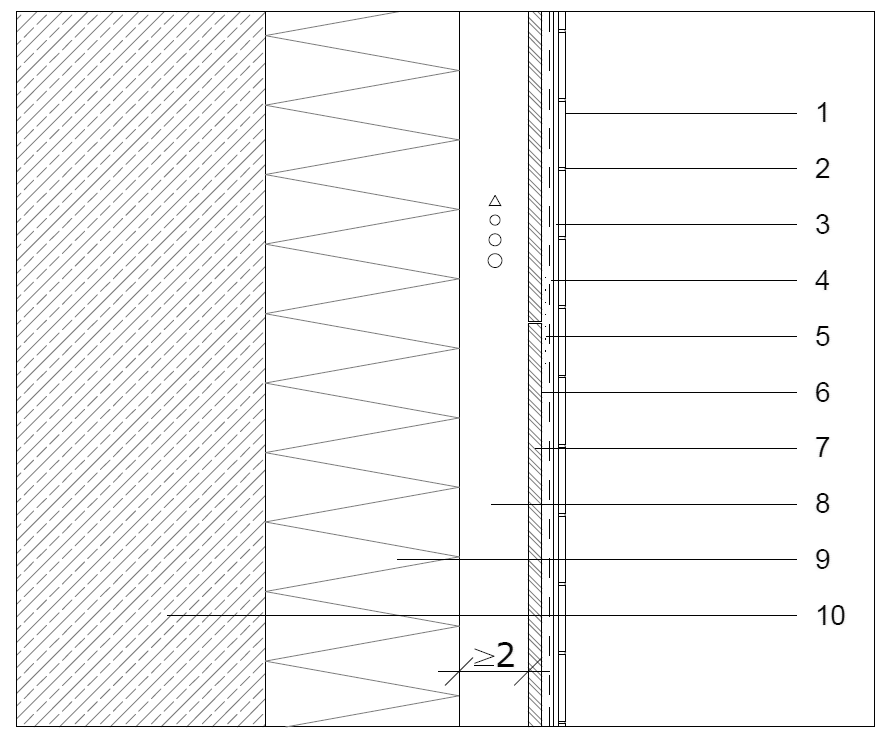

Delta Elements FACADE CERAMIC can be processed on suspended, rear-ventilated plaster support systems which are certified by construction authority. Our processing instructions, the processing instructions of the facade system manufacturers and the below listed DIN norms and guidelines have to be observed. You will find our processing instructions at the download center. Further technical information is available on request.

1 Delta Elements FACADE CERAMIC

2 System-joint mortar, slurry method (except Vals struc)

3 System-adhesive mortar

4 System-equalizing mortar (possibly)

5 System-basic plaster with textile

6 System-priming coat

7 System-facade carrier plate

8 Rear ventilation/aluminium construction

9 System-thermal insulation plate, doweled

10 Sustainable massive ground

Standards and directives

DIN 18157 Installation of ceramic coverings using the glue-fixing method

DIN EN 12004 Mortar and adhesives for ceramic tiles and panels

DIN 18352 Tiling and paving

DIN 18515-1 Exterior wall cladding – tiles or panels applied with mortar

DIN 18516-1 Ventilated cladding facade systems

DIN 18540 Sealing exterior wall joints in building construction using joint sealing compound

DIN 18202 Dimensional tolerances for building construction

DIN EN 14411 Tolerances for ceramic tiles and panels

ZDB-leaflet: Expansion joints in tile and panel cladding and coverings

All specifications and drawings do not constitute any guarantee in regards to the recommendations provided. Delta Elements assumes no liability and refers to its general business terms and conditions. No rights of any kind can be derived from the contents of this information. The respective current version and the general business terms and conditions can be found at www.deltaelements.eu; printing errors reserved.

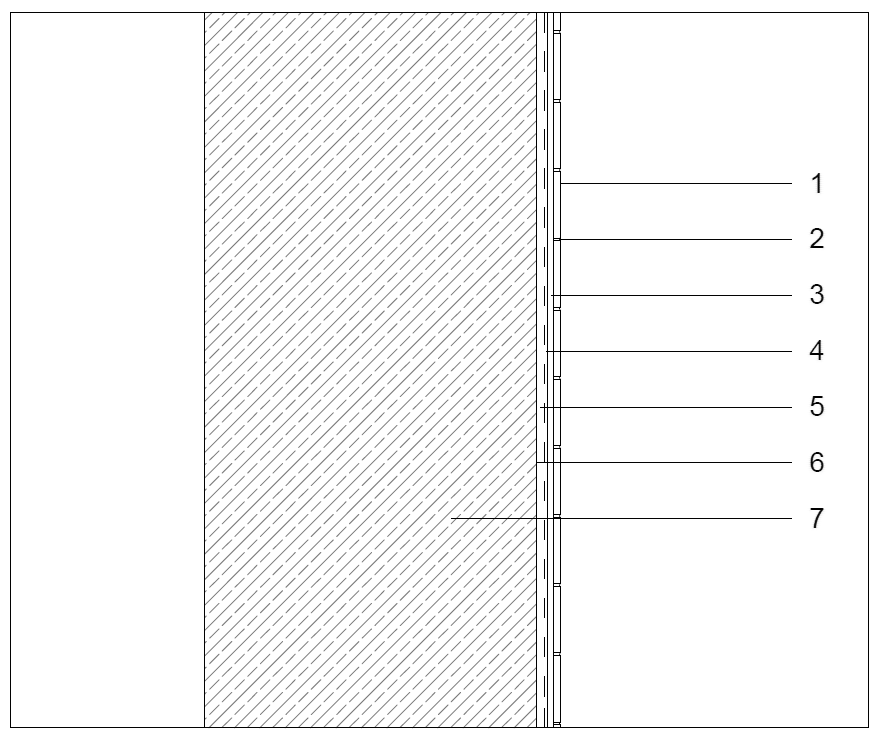

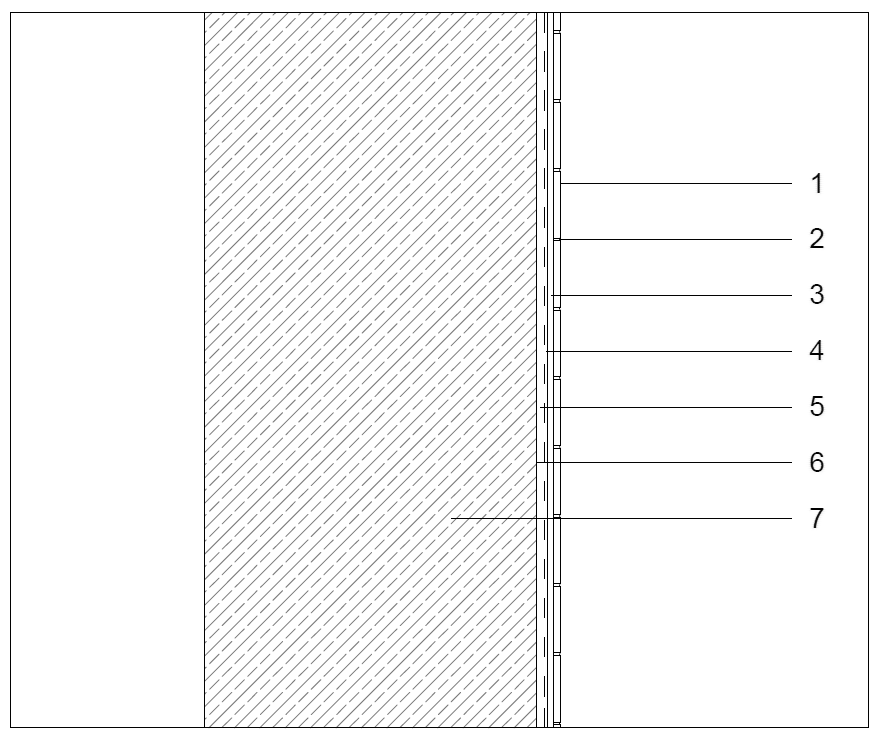

Delta Elements FACADE CERAMIC can be processed on various sustainable massive walls. Our processing instructions, the processing instructions of the facade system manufacturers and the below listed DIN norms and guidelines have to be observed. You will find our processing instructions at the download center. Further technical information is available on request.

1 Delta Elements FACADE CERAMIC

2 Joint mortar, slurry method (except Vals struc)

3 Adhesive mortar

4 Equalizing mortar

5 Basic plaster with textile

6 Priming coat

7 Sustainable massive ground

Standards and directives

DIN 18157 Installation of ceramic coverings using the glue-fixing method

DIN EN 12004 Mortar and adhesives for ceramic tiles and panels

DIN 18352 Tiling and paving

DIN 18515-1 Exterior wall cladding – tiles or panels applied with mortar

DIN 18540 Sealing exterior wall joints in building construction using joint sealing compound

DIN 18202 Dimensional tolerances for building construction

DIN EN 14411 Tolerances for ceramic tiles and panels

ZDB-leaflet: Expansion joints in tile and panel cladding and coverings

- EWI SYSTEM

- rear-ventilated plaster support system

- MASSIVE

All specifications and drawings do not constitute any guarantee in regards to the recommendations provided. Delta Elements assumes no liability and refers to its general business terms and conditions. No rights of any kind can be derived from the contents of this information. The respective current version and the general business terms and conditions can be found at www.deltaelements.eu; printing errors reserved.

Delta Elements FACADE CERAMIC can be processed on exterior wall insulation systems (EWI system) which are certified by construction authority. Our processing instructions, the processing instructions of the facade system manufacturers and the below listed DIN norms and guidelines have to be observed. You will find our processing instructions at the download center. Further technical information is available on request.

1 Delta Elements FACADE CERAMIC

2 System-joint mortar, slurry method (except Vals struc)

3 System-adhesive mortar

4 System-equalizing mortar layer

5 System-basic plaster with textile

6 System-thermal insulation plate, doweled through the textile

7 Sustainable massive ground

Standards and directives

DIN 18157 Installation of ceramic coverings using the glue-fixing method

DIN EN 12004 Mortar and adhesives for ceramic tiles and panels

DIN 18352 Tiling and paving

DIN 18515-1 Exterior wall cladding – tiles or panels applied with mortar

DIN 18540 Sealing exterior wall joints in building construction using joint sealing compound

DIN 18202 Dimensional tolerances for building construction

DIN EN 14411 Tolerances for ceramic tiles and panels

ZDB-leaflet: Expansion joints in tile and panel cladding and coverings

All specifications and drawings do not constitute any guarantee in regards to the recommendations provided. Delta Elements assumes no liability and refers to its general business terms and conditions. No rights of any kind can be derived from the contents of this information. The respective current version and the general business terms and conditions can be found at www.deltaelements.eu; printing errors reserved.

Delta Elements FACADE CERAMIC can be processed on suspended, rear-ventilated plaster support systems which are certified by construction authority. Our processing instructions, the processing instructions of the facade system manufacturers and the below listed DIN norms and guidelines have to be observed. You will find our processing instructions at the download center. Further technical information is available on request.

1 Delta Elements FACADE CERAMIC

2 System-joint mortar, slurry method (except Vals struc)

3 System-adhesive mortar

4 System-equalizing mortar (possibly)

5 System-basic plaster with textile

6 System-priming coat

7 System-facade carrier plate

8 Rear ventilation/aluminium construction

9 System-thermal insulation plate, doweled

10 Sustainable massive ground

Standards and directives

DIN 18157 Installation of ceramic coverings using the glue-fixing method

DIN EN 12004 Mortar and adhesives for ceramic tiles and panels

DIN 18352 Tiling and paving

DIN 18515-1 Exterior wall cladding – tiles or panels applied with mortar

DIN 18516-1 Ventilated cladding facade systems

DIN 18540 Sealing exterior wall joints in building construction using joint sealing compound

DIN 18202 Dimensional tolerances for building construction

DIN EN 14411 Tolerances for ceramic tiles and panels

ZDB-leaflet: Expansion joints in tile and panel cladding and coverings

All specifications and drawings do not constitute any guarantee in regards to the recommendations provided. Delta Elements assumes no liability and refers to its general business terms and conditions. No rights of any kind can be derived from the contents of this information. The respective current version and the general business terms and conditions can be found at www.deltaelements.eu; printing errors reserved.

Delta Elements FACADE CERAMIC can be processed on various sustainable massive walls. Our processing instructions, the processing instructions of the facade system manufacturers and the below listed DIN norms and guidelines have to be observed. You will find our processing instructions at the download center. Further technical information is available on request.

1 Delta Elements FACADE CERAMIC

2 Joint mortar, slurry method (except Vals struc)

3 Adhesive mortar

4 Equalizing mortar

5 Basic plaster with textile

6 Priming coat

7 Sustainable massive ground

Standards and directives

DIN 18157 Installation of ceramic coverings using the glue-fixing method

DIN EN 12004 Mortar and adhesives for ceramic tiles and panels

DIN 18352 Tiling and paving

DIN 18515-1 Exterior wall cladding – tiles or panels applied with mortar

DIN 18540 Sealing exterior wall joints in building construction using joint sealing compound

DIN 18202 Dimensional tolerances for building construction

DIN EN 14411 Tolerances for ceramic tiles and panels

ZDB-leaflet: Expansion joints in tile and panel cladding and coverings

PROCESSING| STORAGE

The thin-bed method is used as a combined method (buttering-floating). Grouted by using the slurry method (except Vals stuc); the standard joint width is 8 mm, for large formats 10 mm. The optimum processing temperature is between 5 and 30° C. The product has to be stored implicit dry, in the shade, dust- and frost-proof.

The detailed processing instructions can be found here:

To ensure the quality of execution we offer support on construction site in cooperation with our system partners.

Therefore we can provide you with advice for a successful completion of your work.